SUMMERLANDS CHUFFERS

Pearse Earl and Leek & Manifold

Pearse Earl

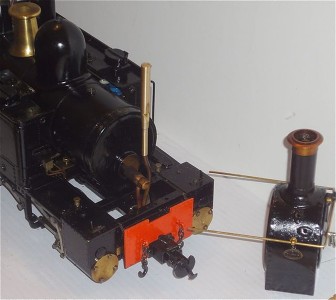

Steve Jackson and I have now fitted a Chuffer to his Pearse Earl - and it was a lot simpler than it looks!

The Chuffer neeeded is the SCGP1 as this Pearse loco has a single 1/8" OD exhaust pipe which is crimped at the top.

The first task is to carefully remove the steam pipes that go into the smokebox.

These are just a push fit into their sockets and it should be possible to remove

the lower one by easing it from under the water feed fipe. If necessary, the

water feed clack box can be removed.

Next, measure down from the top of the chimney to the top of the exhaust pipe

inside. I used the depth gauge on a digital caliper, but you could use a rod and

mark it at the top of the chimney when it rests on the exhaust. On this loco, the measurement was 14mm. Make a note of it.

Now turn the loco on its side on a soft cloth or cardboard and you will see three

brass screws under the smoke-box ( two of these are through a brass strip).

Remove these screws and stand theloco on its wheels again. The smoke-box

can now be easily removed.

You will see the exhaust which rises from between the frames and is bent round the steam pipe.

You want the top of the Chuffer to end up 5mm below the top of the chimney so subtract 5mm from the measurement you recorded (14 - 5 = 9mm) and mark this distance from the top of the Chuffer with a pencil or marker.

Now if you hold the Chuffer against the exhaust with your mark level with the top of the exhaust, you have the finished position of the Chuffer. Mark the exhaust pipe with a small scratch at the bottom of the Chuffer fitting tube. Then measure 20mm up from the scratch and that is your cutting point - as 20mm of the exhaust will push into the tube.

Before cutting, ensure by gentle bending, that this 20mm is as straight as possible as it will be a tight fit in the tube. When you are happy with it, protect the boiler with a cloth and cut the exhaust with a fine hacksaw or cutting disc. Use eye protection if the latter. Now clean off the burrs with a fine file and put a slight chamfer on the top of the pipe to ease fitting.

Now push the Chuffer firmly into place - if it needs a slight tap, make sure you support the exhaust. If it is just too tight, check for straightness again and if necessary, you can shorten the exhaust more to give a minimum of 10mm insertion.

Now test fit the smoke-box and adjust the pipe by bending the exhaust below the Chuffer tube to insure that the Chuffer is central and that the sound slot is not against the Chimney wall.

Pearse Leek & Manifold

Ian Webb in New Zealand has now fitted an SCGP1 Chuffer to his Pearse Leek & Manifold - he reports: "Have test run the L&M and am very pleased with it. The pipe produces a very powerful chuff at reasonable speeds and at slow speeds with a good load it is most realistic and impressive."

Ian's notes and photos are below:

1. Turn loco upside down and remove 2 cheese head brass screws from between the inlet and exhaust steam pipes.

2. Turn loco right way up and remove smoke box by sliding forward clear of boiler and blower steam pipe and lifting clear of exhaust pipe.

3. Cut exhaust pipe 54mm above floor plate. Clean and lightly chamfer cut and ream hole. Clean exhaust pipe above super heater tube to aid fitting.

4. Cut 5mm from end of chuff pipe. (This is optional but will ease bend round superheater tube) Clean and ream cut.

5. Work chuff pipe over exhaust pipe until top of chuff pipe is 104mm above floor plate.

6. Tighten bend of exhaust pipe round super heater tube until chuff pipe is vertical and central.

7. Re fit smoke box, ensuring blower pipe relocates in the smoke box union.

8. Loosely fit both cheese head screws. A dab of blue tack on the end of the screw driver helps.

9. Ensure smoke box is fitting properly and chuff pipe is 5mm below top of chimney. Tighten screws.

Very easy to fit. You will note in the photo that I did not reduce the length of the chuffer. I would recommend that this be done though to ease bend round.

If you fancy improving the Chuff on your Pearse Earl, then click here for a detailed and fascinating account by David Pearson, detailing how he went about it and some of the thinking behind it.