SUMMERLANDS CHUFFERS

Roundhouse Sandy River & Rangely Lakes No 24

Ken Wright was the first to tackle this loco and his report follows:

"The main problem with the Sandy River is that the smokebox is secured by several screws, but these are a bit tucked away and are obscured by the high running boards. These could be removed, but RH has generously coated them with paint. There are also two smokebox stays which disappear into the front pilot beam, and suffer from the same coating of paint. I was really afraid of damaging the paintwork, especially the running boards, so I was trying to think on another approach. The smokebox door plugs in, so I wondered if I could cut the pipes from the front with the smokebox "in situ".

I even bought a cheesecutter type wire saw that I thought I could pass behind the pipes and cut them that way. In fact, the wire saw was too stiff to attempt this, and so I was back to square one. After practicing on a piece of spare pipe, I decided to use a fine hacksaw blade - minus the handle! With padding for surrounding areas, and my long-suffering wife holding the pipe steady with a pair of pliers, I attacked it. After a few minutes the pipe was cut, and after a clean up with a fine file and finishing paper the job was done. I attached the chuffer by pushing it down the chimney and after a few attempts managed to snugly push it onto the exhaust pipes. Success!

I took it straight out to try on my rolling road. I was absolutely delighted with the end result - it sounds fantastic!"

Terry Keep has also fitted the Chuffer to his Sandy River No.24 and adds the following:

"I followed Ken Wright’s method on the Fitting Notes page of the website, but working single-handed found the following helpful:

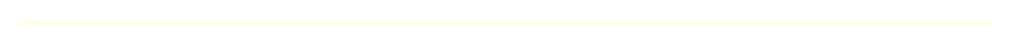

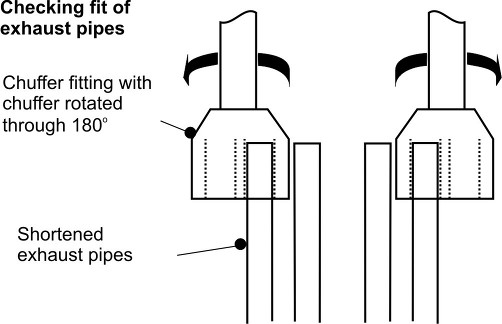

I made a fitting gauge out of a piece of plastic tubing and a clamp. I pushed the tube down the chimney (sorry – stack) so that it enclosed the exhaust pipes and the bottom end gave a cutting guide. A simple clamp on the tube rested on the top of the chimney to hold it in position - it did squeeze the tube a bit - but it works!

Holding the top end of the tube enabled me to steady the exhaust pipes while cutting with a fine junior hacksaw blade. A metal pipe might be better and I did need a bit of help with a pair of snipe-nosed pliers towards the end.

The cutting height worked out at 71mm, (not 72 as in the Lady Anne instructions – maybe I measured it wrong). The clamp squeezed the pipe a little but the arrangement worked:

The pipes were cleaned up by inserting a flat swiss file down the stack, and then through the smokebox door hole.

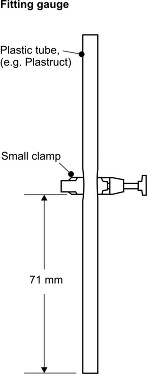

While cleaning up the pipes I found it useful to try each pipe in turn in the holes in the chuffer fitting, by rotating the chuffer through 180 degrees:

Terry has now added the following note:

A better method than using a clamp would be to drill through the tube and insert a piece of rod (or the drill that you used) to form a cross-piece that would sit on top of the stack.(Make sure that the 71mm dimension is correct)

You can see Terry's loco in action here at the bottom of Video Page 6

Lindsay Newton followed the notes on this page - and here are his own notes and photos - in his own special Pine Tree Junction style!

"I followed Ken's and Terry's instructions from the Summerland Chuffer website and found it much easier than I expected. I had successfully fitted a Summerlands Chuffer to our Roundhouse Jack Special Edition and our Silver Lady, but was full of fear and trepidation at tackling our magnificent Sandy River. I don’t mind taking a hacksaw to most things, but our Sandy River is something very special. After the dramatic transformation that a chuffer made to Jack and Silver Lady, Sandy River was sounding very deficient in the sound department so the deed had to be done! With my printed page beside me, and some email encouragement from Chris Bird, I assembled the tools and in true Pine Tree Junction style, brought the camera along as well. If I was going to mess this up, I would need photographic evidence! Anyway, all went well and I successfully fitted the Summerlands Chuffer to Sandy River without any problem at all. What a fantastic sound she now makes. You can check this out for yourself by clicking the video below. Many thanks Chris and Nigel for inventing a great little addition to our superb Roundhouse locomotives!

Here are my step by step instructions.

1. Unscrew the small nut and bolt under the smoke box.

2. Gently pull out the smoke box door to reveal the two cooper steam pipes.

3. Drill a small hole in a scrap piece of copper pipe, 71mm from the bottom

4. Slip a small piece of wire into the hole to rest on the top of the chimney/smokestack

5. Lower the cooper pipe into the smoke stack so the piece of wire rests across the top

6. Mark the two steam pipes with a file across the bottom of the copper pipe.

7. Place a piece of thin wood behind the pipes against the boiler to act as a guard.

8. Hold the two steam pipes with a pair of pliers or a small clamp.

9. Using a small hacksaw blade, slowly begin to cut the pipes. Take your time - slowly does it!

10. Remove the off cuts from the two steam pipes.

11. File the top and inside of the remaining steam pipes.

12. Slip the chuffer down the smoke stack.

13. Gently fit the chuffer onto the first steam pipe.

14. Pull it off and try the chuffer on the second steam pipe.

15. When both fit, gently tap the chuffer onto both steam pipes.

16. Replace the smoke box door.

17. Job done!

John Blakeley in Australia has found a different method. He writes:

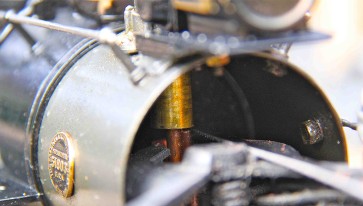

I have a high frequency multi-function tool ( there are several brands) & it has a small 10mm blade that I have used to cut the exhaust pipes in another loco. Its reach is only 37mm approx. & access on the SRRL loco is blocked by the protruding head light. With the smoke box cover removed one can see 2 nuts (just visible in the left hand photo above) which allow removal of the head light & stack assembly . This allows the tool to reach the 2 pipes & also facilitates the bracing / holding of the pipes during cutting.

Note - if using this method, make sure that you protect the front of the boiler before cutting and that you have a steady hand!

There are a number of different ways of fitting a Chuffer to this fine loco. Below are four different approaches - though there may be more!