SUMMERLANDS CHUFFERS

Roundhouse Argyll (and other early Roundhouse)

These note also appy to many early Roundhouse type locos where the smokebox is not easily removable. This may include Lady Anne, Jack, Fowler etc.

The first thing to be aware off is that there are three types of smokebox fitting:

1. Early type.

Here the smoke-box casting is riveted to the front footplate and the exhausts and superheater pass through a hole in the bottom of the casting. This means that even if you drill out the rivets (to replace them with screws) you cant remove the smoke-box. David Turner's account below tells how he got round this, but the more straightforward option is to remove the boiler to access the exhausts. This type will have short exhaust stubs which may require you to lengthen the chuffer connecting pipe or order a special longer one.

You can check if yours is this type by looking at the back of the smoke-box saddle to see

if there is a gap. If you can't see then investigate with a bit of bent wire. If there is no

gap - then it is the early type.

2. Mid type.

Here the difference is that the superheater and exhausts pass through an open backed

slot in the base of the smoke-box casting. You can look or probe for this as above. If it is

there, it means that drilling out the rivets will allow you to remove it as Chris Haley

describes below. Again the exhausts are likely to be cut short.

3. Late type

Here the slot is there as in the mid type, but the smoke-box casting is screwed on and

can be removed if you can get at the screws. Photos of this type are below.

Fitting notes - Early type.

It is the early type that presents some problems so here are David Turner notes on how he did it. It is also worth reading the pages on fitting to the Fowler which can present similar problems.

"Roundhouse Argyles present a modest problem of access to the exhaust pipes but the way forward is simple. First unscrew the middle two of the four small screws on the front footplate ledge.

Next, carefully prize the brass handrails out of their holes in the sides of the smokebox. It is possible by a modest amount of bending to release them from the first set of retaining clips on the boiler, without distorting the rails. Twist the handrails through 90 degrees so that they lie flat against the smokebox under a little spring tension but not enough to prevent the removal task. Now the smokebox is loose enough to assist the next step.

The smoke box is also held by a single central screw to one frame spacer. Its head can be seen in profile at the rear of the smokebox, under the boiler but it is not possible to get a conventional screwdriver into the slot, even through the chimney hole once the chimney is pulled out of its housing. However, this screw is unlikely to be tight. It has been bathed in oil and it has no locknut so it should be a simple matter to wind it out by using a screwdriver blade on the side of the nut head. A long pair of long-nosed pliers would also work.Try to remember that anticlockwise undoes nuts!

Once this nut is free the smokebox may move more but still not be removed because of the superheater tube. (this passes through the large round hole and then curves back into the the boiler flue). This is not a big problem. Turn the locomotive on its back, preferably nested on foam or a pile of old cloths. With a fine round profile craft file carefully extend the screw hole in the baseplate of the smokebox so that you have a fore and aft slot wide enough for the 1/8th inch superheater tube to pass through. (You could used a burr on a Dremel or similar mini drill - but make sure you protect the boiler if you do this) If you make this slot generous you will find reassembly easier. From here on, the fitting of the chuff pipe is as usual.

On reassembly, you can choose whether to replace the rear screw, or not. It seems to make no difference to the stability of the smokebox unit which, after all, snugly sleeves over the boiler which is immovable anyway and is prevented from sliding forward out of place by the two front screws.

Fitting Notes - Mid Type

Here are Chris Haley's notes on fitting to this version.

"Well finally got my Argyll and me in the same place with a little time to try and fit the chuffer - and it is proving to be a bit of a ***! I can see it would be a doddle on the later version, but mine is the earlier version with smokebox rivetted to footplate. David Turner's instructions proved very useful in getting the smokebox a bit loose - although revoving the screw fixing it to the frame spacer took a while (and I don't see it could ever be replaced). But even with it loose removing the smokeboxis proving a major challenge. The problem, as David notes, is the superheater pipe. This passes through a hole on the piece of footplate to which the smokebox is riveted. David suggests cutting a slot through the footplate. This would be a major efffort on mine as the superheater pipe is soo tight against the edge of the hole to allow it to be moved for filing. Antway, I've put it on hold for a moment whilst I think it through..........

...........Having slept on it I decided the easiest option was simply to drill out the rivets holding the smokebox to the footplate. I was worried that these might be difficult because, like the screws on the later model, they are partly obscured by the steam pipes. But in fact it was dead easy - no more that a minute or two with a minidrill. Removing the front buffer/coupler eases access a bit and this way there is no need to remove any screws including the inacccessible one under the smokebox. The smokebox then is easily removed and the remainder of the rivets can be drifted out.

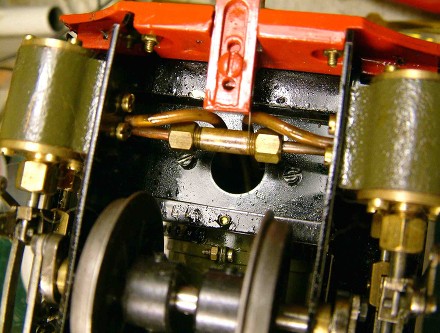

The plan is to tap rivet holes in the smokebox and replace the rivets with screws as in the more recent version - allowing rapid removal if adjustments need to be made once the chuffer is fitted. However, having done this I discovered one more hurdle to deal with - the exhaust pipes on my Argyll are cut only just above the footplate and were wedged side-by-side into a single piece of slightly flattened brass tupe which takes the exhaust into the chimney (this must be original fitting as I very much doubt that the smokebox had been removed previously - and I assume may be a problem on some other RH locos as well). The shortened pipes mean that the chuffer slot will be too low - not within the chimney - if fitted on these."

In fact Chris first tried lengthening the two pipes, but then just lengthened the single pipe between the Chuffer and the adapter. Please note that we can supply a replacement Chuffer with a longer pipe if required.

Fitting Notes - Late Type

Sam Evans first alerted me to the late type when he found the fitting very easy.. His photo show two screws holding the smoke-box casting to the front foot plate. With these removed, the smoke-box can be removed. These versions also have the longer exhausts which will need cutting to size. Sam opted to fit his Chuffer 3mm down from the chimney top as the Argyll chimney is quite short. This put the cut height at 70mm from the chimney top.

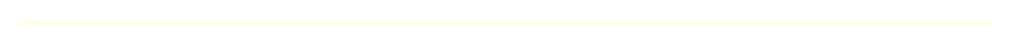

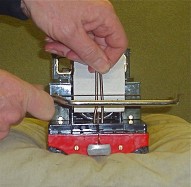

A late type Argyll has recently joined the Summerlands loco shed and the photos clearly show the slotted smokebox and the fitting stages. The top of the chuffer has been painted matt black.

Above you can see the sequence of measuring, marking, cutting and then the chuffer fitted.

Left you can clearly see the screws on Sam Evans' Argyll. He was lucky!